- Course

Creating Printed Circuit Boards with EAGLE

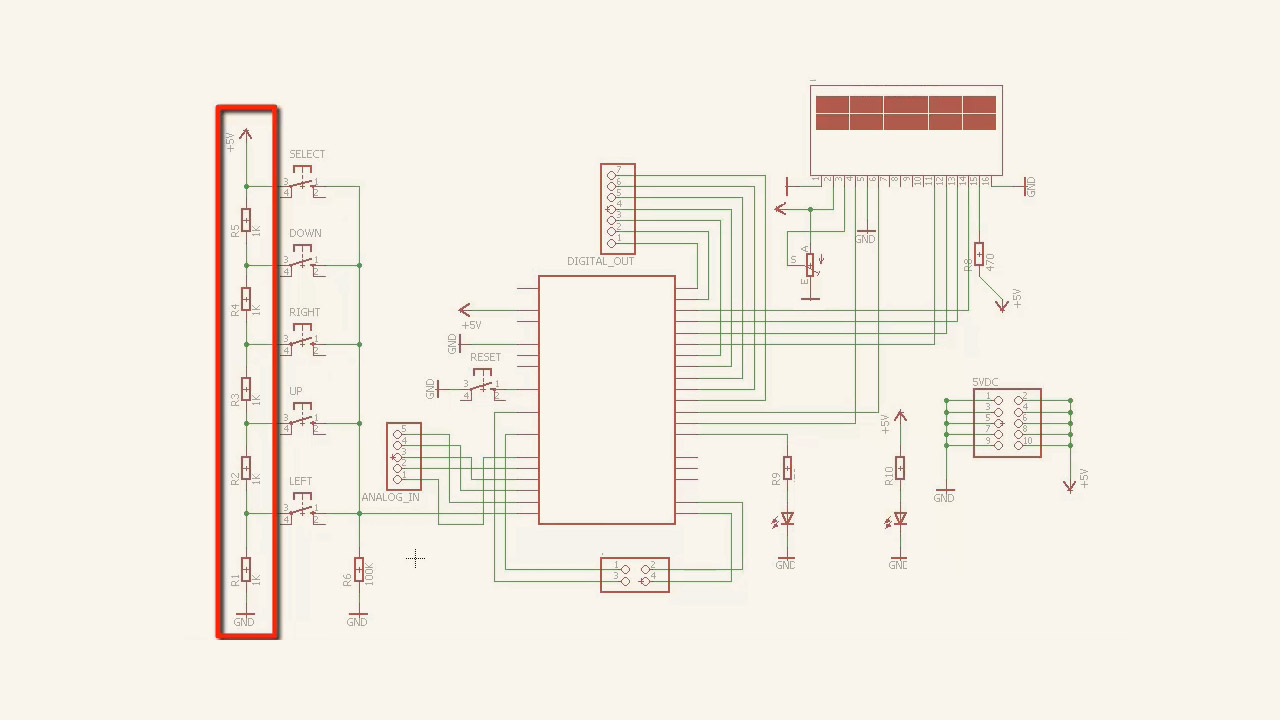

This course will teach you how to create printed circuit boards using the EAGLE PCB software from Cadsoft. The course works through the design and construction of an actual project from start to finish: an LCD/Keypad shield for an Arduino UNO.

- Course

Creating Printed Circuit Boards with EAGLE

This course will teach you how to create printed circuit boards using the EAGLE PCB software from Cadsoft. The course works through the design and construction of an actual project from start to finish: an LCD/Keypad shield for an Arduino UNO.

Get started today

Access this course and other top-rated tech content with one of our business plans.

Try this course for free

Access this course and other top-rated tech content with one of our individual plans.

This course is included in the libraries shown below:

- Core Tech

What you'll learn

If you are an electronics enthusiast and need to make circuit boards for your electronic projects, then EAGLE, a professional quality PCB software program, allows you to go from an experimental designs to a completed circuit board. It is available in a free version for non-commercial use. This course works through a sample project, an LCD/keypad shield for an Arduino UNO, and teaches the schematic creation, board layout, and manufacturing functions of EAGLE. The course wraps up with the actual assembly and testing of the circuit. Sample code for the Arduino, as well as all the EAGLE files, are provided for the demo circuit. You will gain a full understanding of the application and concepts that can be used to design boards for other development platforms or their own circuit applications.