- Course

Fusion 360 – Design for Injection Molding

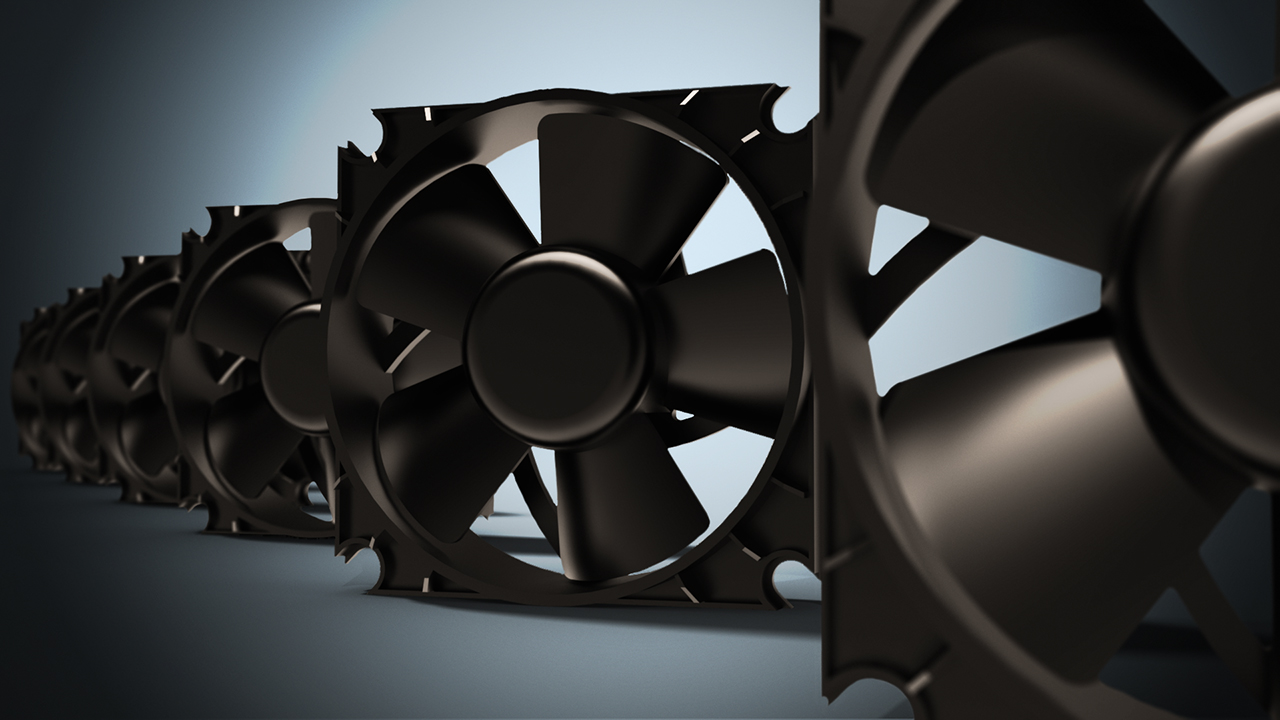

This course will cover how to design two very different parts and how to analyze the multiple methods you have available to create your own design. Learn how to create your own amazing products using Fusion 360. Software required: Fusion 360.

- Course

Fusion 360 – Design for Injection Molding

This course will cover how to design two very different parts and how to analyze the multiple methods you have available to create your own design. Learn how to create your own amazing products using Fusion 360. Software required: Fusion 360.

Get started today

Access this course and other top-rated tech content with one of our business plans.

Try this course for free

Access this course and other top-rated tech content with one of our individual plans.

This course is included in the libraries shown below:

- Core Tech

What you'll learn

Part of the challenge of injection molding is less about the function of the part and more about the geometry requirements to make a part mold-able. In this course, Fusion 360 – Design for Injection Molding, you'll learn the basics of Injection Molded design, and the tools in Fusion 360 needed to achieve them. First, you'll learn about basic feature creation in Fusion 360. Next, you'll learn how to design for drafting. Finally, you'll learn how to tackle complex molding design issues and how to analyze drafted parts. By the end of this course, you'll be more knowledgeable about designing your own injection molded parts. Software required: Fusion 360.