- Course

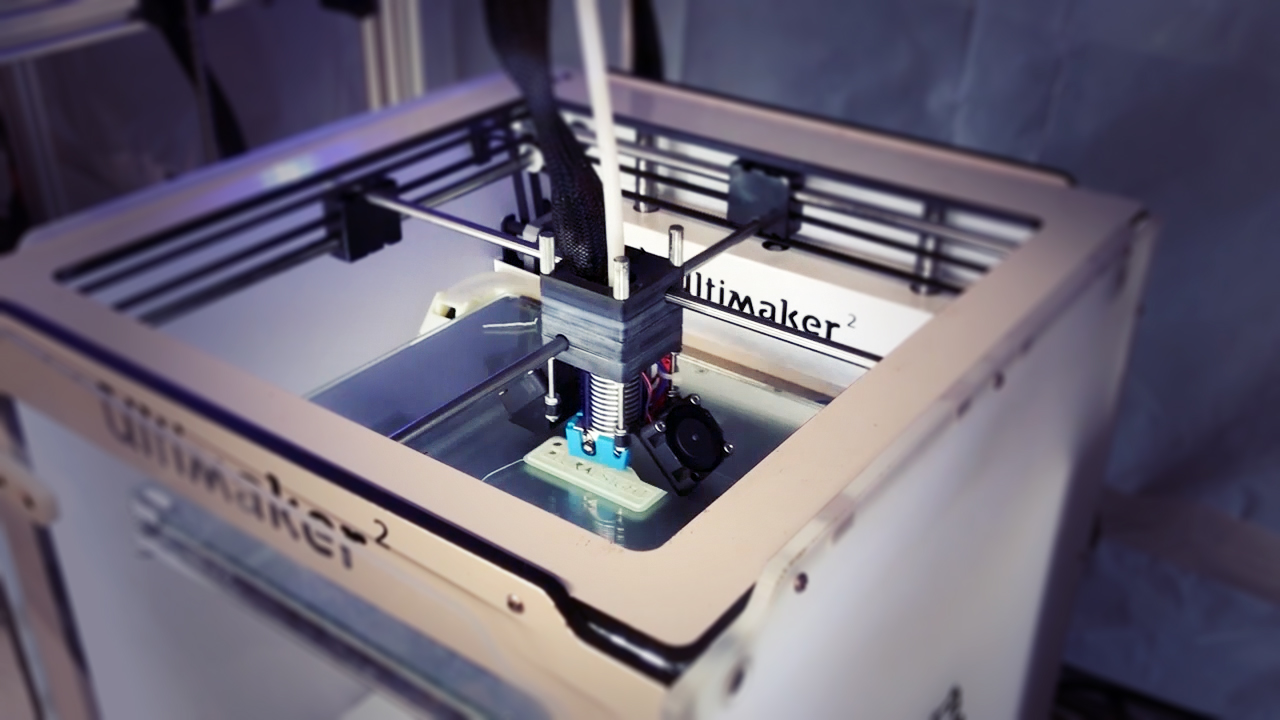

3D Printing: Designing for FDM with Inventor

Designing parts for 3D printing can be more involved than it appears at first glance. This course will help you design parts that can be easily printed using Autodesk Inventor.

- Course

3D Printing: Designing for FDM with Inventor

Designing parts for 3D printing can be more involved than it appears at first glance. This course will help you design parts that can be easily printed using Autodesk Inventor.

Get started today

Access this course and other top-rated tech content with one of our business plans.

Try this course for free

Access this course and other top-rated tech content with one of our individual plans.

This course is included in the libraries shown below:

- Core Tech

What you'll learn

While 3D printing is an amazing tool for turning ideas into physical objects, not all 3D models translate well from 3D modeling software to real life. In this course, 3D Printing: Designing for FDM with Inventor, you will learn how to create 3D models in Autodesk Inventor with the end goal of 3D printing the model in mind. You will first learn about the basics of 3D printing and Inventor. Next, you will get to see proper part orientation, how to avoid as well as how to deal with over hangs on your part. Finally, you will see different methods to process difficult parts so they can be easily printed. When you are finished with this course, you will have a solid understanding of how to design parts for manufacturing on a 3D printer. Software required: Autodesk Inventor 2017, Cura 2.6, Meshmixer 3.2.