- Course

SOLIDWORKS Sheet Metal - Enclosure Part Design

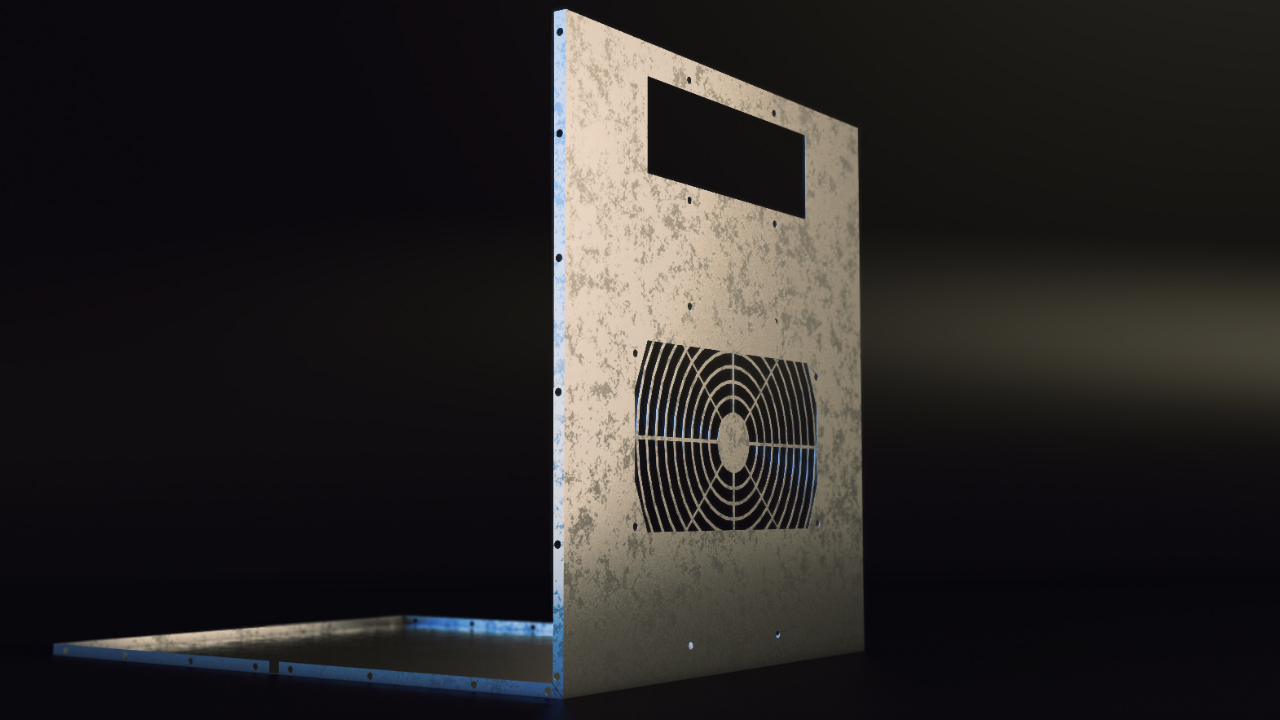

Throughout these lessons, we will be creating a sheet metal part for an electrical enclosure confined and driven by a design envelope along with various tools including the edge and miter flanges, bolt holes, a vent, and various other features. Software required: SOLIDWORKS 2012 and up.

- Course

SOLIDWORKS Sheet Metal - Enclosure Part Design

Throughout these lessons, we will be creating a sheet metal part for an electrical enclosure confined and driven by a design envelope along with various tools including the edge and miter flanges, bolt holes, a vent, and various other features. Software required: SOLIDWORKS 2012 and up.

Get started today

Access this course and other top-rated tech content with one of our business plans.

Try this course for free

Access this course and other top-rated tech content with one of our individual plans.

This course is included in the libraries shown below:

- Core Tech

What you'll learn

Throughout these lessons, we will be creating a sheet metal part for an electrical enclosure confined and driven by a design envelope along with various tools including the edge and miter flanges, bolt holes, a vent, and various other features. We will cover the creation of a portion of an electrical enclosure to house equipment for assembly line processing machines. You will also learn how to apply basic properties for your sheet metal part, a base flange, edge flange, miter flange, the hole wizard, and the vent fastener feature as well as various options and methods. Ultimately, a sheet metal part model is created and ready to be assembled with other sheet parts, components, and fasteners to create an electrical enclosure. Software required: SOLIDWORKS 2012 and up.